-min.png)

Consultation with engineering specialist is recommended for addtional specifications according to the building / construction type.

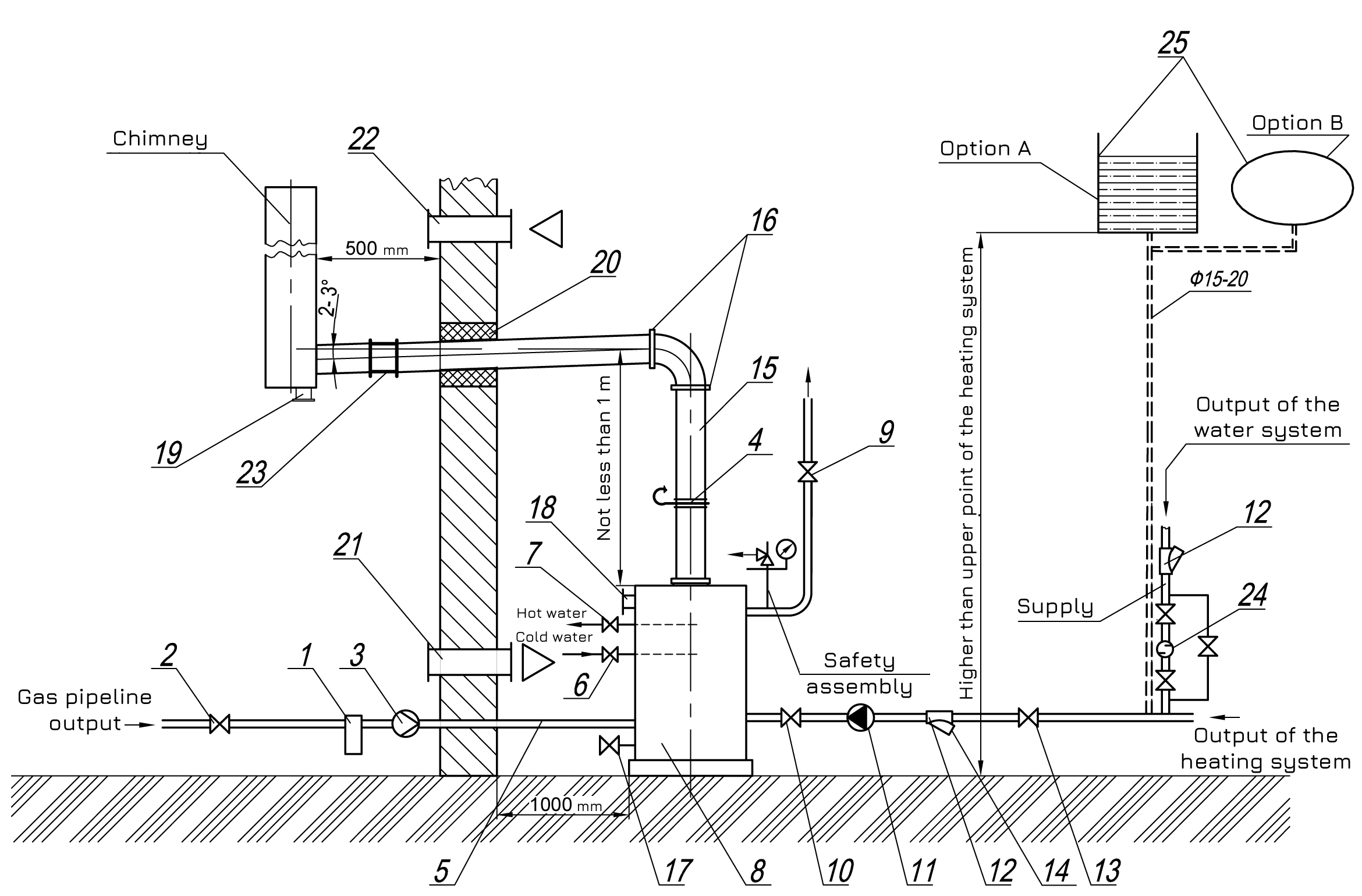

RECOMMENDED CONNECTION DIAGRAM FOR VERTICAL GAS BOILERS WITH MIDDLE POWER BB-535...4035 GA

- Gas filter

- Ball valve

- Flow meter

- Shiber

- Gas pipeline

- Ball valve at the cold water inlet

- Ball valve at the outlet of hot water

- Boiler

- Valve / valve on the supply pipe of the heating system

- Valve / valve on the return pipe of the heating system

- Circulation pump

- Water filter

- Cork for removing dirt

- The flue duct (chimney)

- Flange connection for periodic cleaning of the flue

- Drain valve

- Metal plug

- Condensate drain plug

- Fireproof material

- Hole for ventilation with cross-section of at least 1.5-2.0 Ø of the flue section

- Hole for exhaust ventilation with a cross section of at least 1.5-2.0 Ø of the flue section.

- Explosive valve

- TLU (or polyphosphate dosing)

- Ball valve on the supply water line

- Expansion tank

Notes

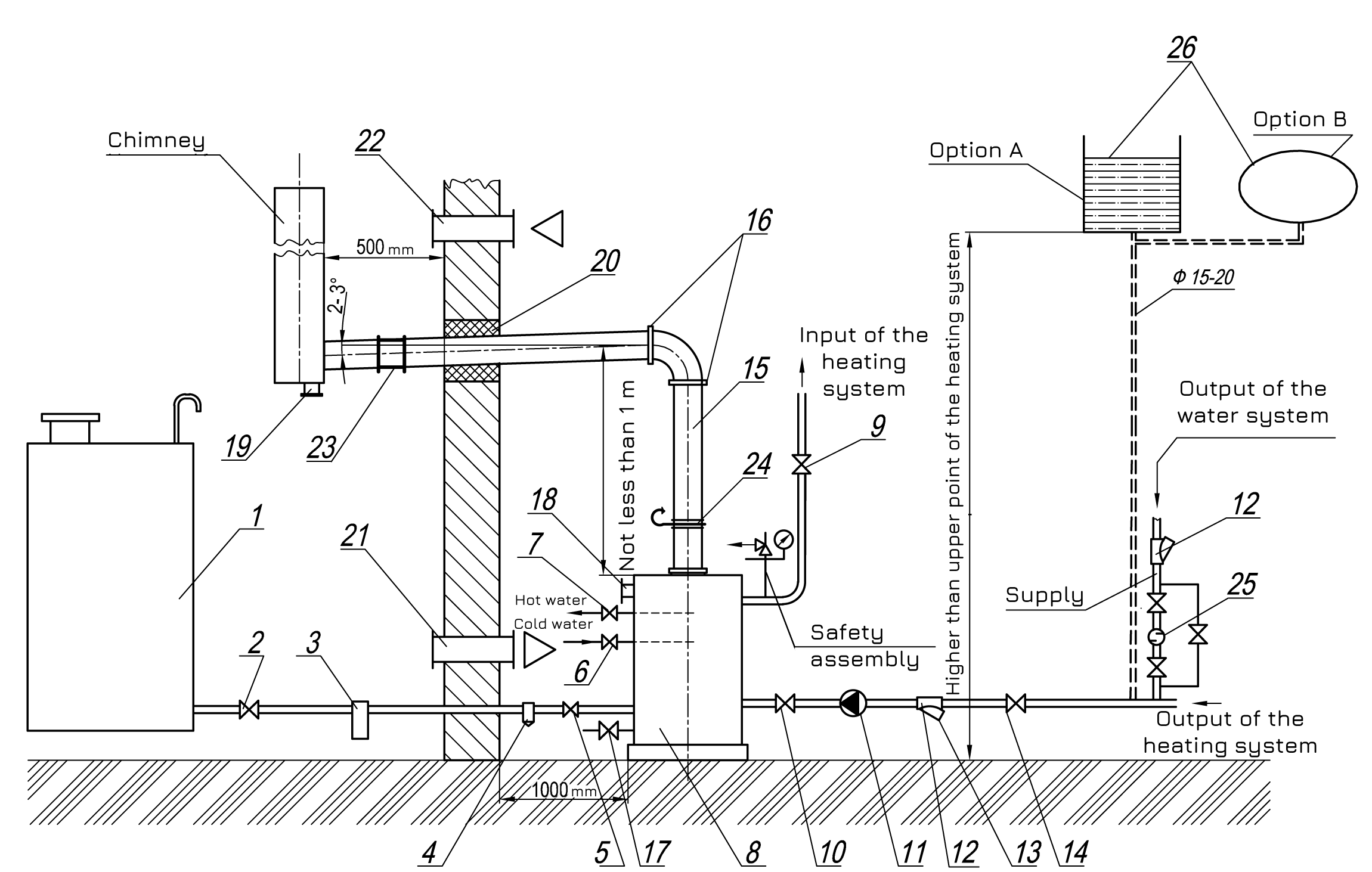

- To improve the reliability of the heating system, it is recommended to install two pumps with fittings and an automatic transfer system.

- In the boiler piping scheme, you can use: option A - atmospheric tank or option B - membrane expansion tank.

RECOMMENDED CONNECTION DIAGRAM FOR VERTICAL DIESEL BOILERS WITH MIDDLE POWER BB-535...4035 FA

- Fuel Capacity

- Ball valve

- The sump (mud tank)

- Fuel fine filter

- Ball valve at the cold water inlet

- Ball valve at the outlet of hot water

- Heating boiler

- Valve / gate valve on the supply pipe of the heating systems

- Valve / valve on the return pipe of the heating systems

- Circulation pump

- Water filter

- Cork for removing dirt

- Flue duct (chimney)

- Flange connection for periodic cleaning of the flue

- Drain valve

- Metal plug

- Condensate drain plug

- Fireproof material

- Air inlet (a cross section of at least 1.5-2.0 Ø of the flue section)

- Hole for exhaust ventilation section (not less than 1.5-2.0 Ø of the flue section)

- Explosive valve

- Shiber

- TLU (or polyphosphate dosing)

- Ball valve on the supply water line

- Expansion tank

Опубликовано: 2018-07-27

Опубликовано: 2018-07-27Дополнено: 2019-04-17

Buran Boiler